OPERATIONAL HO SCALE TRACTION COUPLERS

by the Southern California Traction Club (SCTC)

Dave Garcia & George Huckaby

May 10, 1998

BACKGROUND

One spring day in 1995, we had the opportunity to thumb through an HO scale Kato catalogue and while flipping the pages by all the Japanese prototype rapid transit equipment, our eyes caught on the front end of one three car set. There was a very prototypical looking traction coupler on the front of the first car.

We were fortunate to know a fellow model railroader from Japan, who occasionally comes to the United States and just happened to have a model of that very car, so he agreed to show it to us and we were surprised to find that it was indeed a working traction coupler. The coupler had a drawbar and mounting hole similar in appearance to a Kadee No #5 but thicker. However, it truly worked and looked better than anything we had seen to date. We showed the model coupler to Dave Garcia, one of the mechanical experts at the Orange Empire Railway Museum, Perris, CA who later became a member of the Southern California Traction Club. He concluded that the model coupler was a close rendition of an Ohio Brass Form 20 Tomlinson coupler. A good example of the prototype use of this coupler was on the Key System cars in the East Bay Area of San Francisco.

PROTOTYPE DATA

Broadly speaking, in the United States, there were three basic designs of fully automatic traction or transit couplers. The oldest type, Tomlinson, originated in Denver. For years this type was manufactured by the Ohio Brass Company and was offered in several sizes and with a variety of air brake and electrical connection options. Examples of lines that used these couplers were the Illinois Central suburban electrification, the Chicago, Aurora & Elgin Pullman, Cincinnati and St. Louis steel cars, the San Francisco Bay Key System (several classes), the Indiana Railroad 1930 High Speed Cars and the Boston Elevated Railway PCC and elevated car fleets.

Without a doubt, the lions share of this business went to the Westinghouse Air Brake Company who offered a variety of sizes and options for their line of couplers, all of which bear a "family resemblance". Probably the earliest common type was the type C-3 or C-3-A coupler found on the Sacramento Northern cars 22 through 25, the Syracuse & Binghamton, the Portland-Lewiston Interurban and Pacific Electric cars 446 through 448 and 450 through 464. The type C-3 automatic coupler made the air connections at the time the cars were coupled. The type C-3-A also made electrical connections. The type C-3 couplers were installed on at least two of the Hedley-Doyle Stepless Cars owned by the Pacific Electric Railway but were removed quickly after the handling of a train on curves was questioned. Similar but more massively built models were the type F and J used on the Interborough Rapid Transit (IRT) subway lines in New York City. By far the most common type was (and is currently) the type H-2-A and its succeeding versions, the types H-2-B and H-2-C which are still used on about 6200 NYCTA (New York City) subway cars. The H-2-A probably was first used on the Pacific Electric 1200 class steel cars, and was also used on the Pacific Electric 1100 class suburban cars and the much larger 300, 400 and 450 classes of Pacific Electric "Blimps". Some type H-2-B couplers were also used on the Illinois Terminal St. Louis built streamlined passenger trains of 1949. The type H-2 is a massively built piece of machinery which automatically makes the air brake and electrical connections while coupling the cars. Coupling is accomplished by simply pulling two couplers together. Uncoupling is accomplished by merely throwing a small lever in the cab (or under the platform on the NYCTA cars) and then, in order, the air lines are closed, the electrical connections are broken, and then with much hissing of air and two loud bangs the cars are uncoupled. Underneath the coupler head is the electrical portion, a large variety of these having been supplied down the years, depending on voltage used, number of contacts required, etc.

Another common coupler was the type K-1. This is a smaller design intended for city car use. The type K-1 makes only air brake connections while the cars are being coupled. The San Diego 1915 Exposition cars were equipped with this coupler. Pittsburgh was also a user. The type K-1-A coupler also made the electrical connections and was used on the Brooklyn Peter Witts, The Los Angeles Railway F (1151-1165), H (1201-1450), K (1501-1560) classes, the Pacific Electric "Hollywood" (600-759) class and the PERy 1942 5000 class double end PCC cars among others. Other versions of the type K-1 coupler were used on the Illinois Terminal double ended PCC cars and on Toronto's MU PCC cars.

The third manufacturer was the Van Dorn Coupler Company of Chicago. They marketed a wide variety of couplers, but are probably best known for their link and pin type couplers widely used on old interurban and rapid transit operations. They had a fully automatic coupler rather similar to the Westinghouse type H-2-A, B and C. It is distinguishable by a short narrow probe that "plugs" into the opposite coupler. It has an electrical section below the coupling head. Two sizes of this coupler were available. As far as the writers know, the Philadelphia Market-Frankford Subway Elevated and the Broad Street Subway cars were the only major users of this type of coupler. Today these couplers can be seen at museums such as Illinois Railway Museum that have examples of the 1928 and 1938 Broad Street Subway cars. These are truly massive couplers. As a side note, at the ends of their service lives, spare parts were provided by the Ohio Brass Company.

Both Van Dorn and Tomlinson offered various types of M.C.B. compatible radial "knuckle" couplers, more correctly called "Vertical Plane Couplers". Some of these had built on electrical connectors. Equipment of the Washington, Baltimore & Annapolis are an example. Both manufacturers supplied these extensively to the midwest interurbans in particular. Other coupler manufacturers such as Washburn, McConley & Torley, and Sharon Steel Foundries also offered radial "knuckle" couplers as well.

MODELING TRACTION COUPLERS

Even though Westinghouse automatic couplers were used on the Pacific Electric, we began to experiment with ways to adapt this Kato Tomlinson coupler to a radial bar to use on the model Pacific Electric 300 and 400 series Blimps, the 1100 Class Suburban cars and the 1200 class interurbans, and possibly the "Hollywood" and PCC cars.

We obtained samples of this coupler from the same modeler. They were available in Japan in packages of ten along with the Kato draft gear suitable only for large radius curves. So experimentation began to fashion our own drawbars. After trying both styrene and brass, the styrene method was initially chosen as Method One and using it, the Southern California Traction Club (SCTC) applied these to five Suydam HO scale 400 series Pacific Electric Blimps and some 1200 series cars, all powered models. The club successfully ran a five car train of powered "Blimps" at the clubs initial show, the April 1997 NMRA/PSR/LA show at the South Coast Botanical Gardens in Palos Verdes, CA. and at several shows in the succeeding year. Incidentally, twelve inch radius curves, including an "S" curve were successfully traversed by this train. The Southern California Traction Club has since designated these couplers with the styrene drawbar as the "H-1" couplers.

When attempting to use this method on a modernized Suydam or Soho "Hollywood" car, we discovered that the styrene drawbar was just too large to clear the lifeguards. Note that the couplers on these cars must be removed to remove the chassis from the body, so the mount must be designed to take that level of handling. So the SCTC devised Method Two for these cars and other multiple unit streetcars with fenders mounted under the front platform, and designated these the "H-2" couplers.

PROCEDURE FOR INSTALLING THE Kato "H-1" COUPLER - METHOD ONE

1. The second step will be to remove the base of the coupler leaving only the shank. This is accomplished by cutting the coupler parallel to the mid point of the coupler mounting hole as shown in Figure 1 and then filing the shank down to the size that will slide snugly into a piece of Plastruct STFS-4 .125" square tubing or Evergreen Scale Models StripStyrene Item No. 252 (Walthers #269-0252).

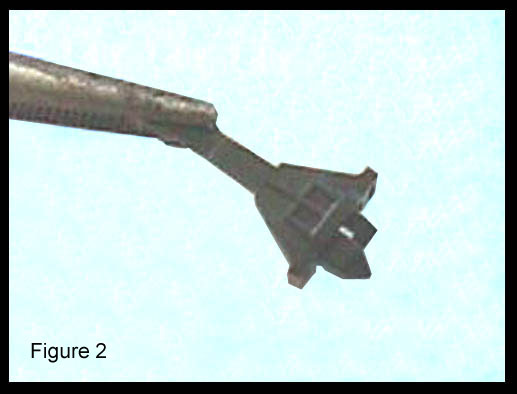

2. The next step is to prepare the drawbar to receive the coupler. Notice that the coupler face has nothing to do with maintaining the coupling of the cars. There is an "L" shaped bar under the coupler that mates with the identical bar on the mating coupler and that is what holds the cars together. We will call this part the coupler connector. To operate successfully, the coupler connector is mounted on a split shaft separate from the coupler head. This split shaft allows sufficient freedom vertically for this coupler connector to operate. To maintain this freedom in the new drawbar, a small notch is cut into the base of the drawbar as shown in Figure 2 .

3. The coupler is then inserted in the prepared end of the tubing in a manner that the coupler connector shank fits just beneath the notched end. If inserted correctly, the coupler connector should have sufficient room for vertical movement to uncouple without breakage. Once the coupler fit is made and a snug fit of the entire coupler shank can be made inside the square tube of the drawbar. Remove, and apply ACC and re-attach inside the coupler drawbar.

4. Two more actions must take place before mounting the coupler to the car body.

a. Obtain some Plastruct MS-60 solid bar stock, .060" by .060", or Evergreen Scale Models Item No. 153 (Walthers 269-0153) and place inside the coupler drawbar from the one remaining open end. When you have inserted the bar stock as far as it will go, then remove and apply generous amounts of Plastruct Cement and reinsert. When the glue is thoroughly set, cut flush with the end of the drawbar.

b. As an optional method of ensuring against pulling the coupler from the modified drawbar, using a #67 drill, drill a hole through the side of the drawbar, through the coupler shank and out the outer side of the drawbar. Then insert a piece of .019 wire, secure with ACC and cut flush on both sides.

5. In attaching to the car body, more than likely you will have a coupler mounting hole already provided. If you are fortunate to have a local source of prototype data or better yet, a nearby museum where prototype dimensions can be readily obtained,you may use such data as a source of information.

a. We found that on a prototype PERy 400 series "Blimp", the length of the drawbar from the center pin of the draft gear to the striking face of the coupler is 51.75" and the face of the coupler is between 12.75 and 16.25 inches from the buffer depending upon the buffer block type. The center of the coupler is 30.5" from the top of the railhead.

b. We also were fortunate to know that the distance from the coupler striking face to the center pin on a Hollywood Car was 72" and the coupler face is 15 inches from the anti-climber. The center of the coupler is 18" from the top of the rail head. Please refer to the matrix below for some typical prototype dimensions provided for your modeling information.

| WESTINGHOUSE COUPLERS - PACIFIC ELECTRIC CARS | ||||||

| CARS/CLASS | COUPLER TYPE | CENTER PIN - DRAFT GEAR | STRIKING FACE TO BUFFER | CENTER OF COUPLER HEAD TO RAILTOP | REMARKS | |

| TO STRIKING FACE | TO CENTER OF CIRCLE IRON | |||||

| 446-447 | C-3 | 60.0 INCHES | 40.0 INCHES | 28.0 INCHES | ||

| 448 | C-3 | 60.0 INCHES | 40.0 INCHES | 28.0 INCHES | ||

| 450-465 | C-3 | 60.0 INCHES | 40.0 INCHES | 28.0 INCHES | ||

| 600-759* | K-1A | 70.0 INCHES | 54.0 INCHES | 15.0 INCHES | 18.0 INCHES | |

| 5000-5029 | K-1-A | 18.0 INCHES | 18.875 INCHES | |||

| 1100-1149 | H-2-A | |||||

| 1200-1251 | H-2-A | 52.0 INCHES | 28.625 INCHES | 9.0 INCHES | 34.0 INCHES | |

| 1252-1263 | H-2-A | 53.0 INCHES | 9.0 INCHES | 34.0 INCHES | ||

| 1299 | H-2-A | 53.0 INCHES | 9.0 INCHES | 34.0 INCHES | ||

| 300-318 | H-2-A | 51.75 INCHES | 26.5 INCHES | 13.75 INCHES | 30.5 INCHES | |

| 400-437; 450-459 | H-2-A | 51.75 INCHES | 26.5 INCHES | 12.75 & 16.25 INCHES | 30.5 INCHES | STRIKING FACE TO BUFFER DIMENSION VARIES ACCORDING TO TYPE BUFFER USED |

| 496-499 | H-2-A | 51.75 INCHES | 26.5 INCHES | 15.0 & 16.25 INCHES | 30.5 INCHES | 15" AT BAGGAGE END; 16.25" AT VESTIBULE END |

| * ALSO LATER 5050 CLASS | All data provided by Dave Garcia, Orange Empire Railway Museum | |||||

c. As a general rule, the radius of the coupler swing was usually concentric with the radius of the anti-climber or buffer, especially on street cars and interurbans where city curves had to be traversed. Models often do not adhere to this fact as mounting the coupler in that position would usually impede the swing of the power truck.

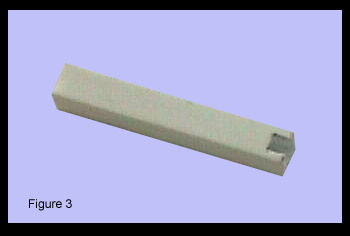

6. Once you decide the proper place to drill the mounting hole in the drawbar, drill a perfectly vertical hole in the drawbar with the same #67 drill and then finish with a #55 drill. Normally, we use 0-80 hex screws with one 0-80 washer to attach the drawbar to the car. In some cases, we have had to tap the existing mounting boss to ensure a correct fit. Since our first applications of these "H-1" couplers were on HO scale Suydam #400 PERy "Blimp" coaches, Suydam #498 "Blimp" combines, and Suydam PERy steel coaches and combines of the 1200 and 1300 series, all of our experience has been limited to these cars. On some of the early imported "Blimps", no mounting boss was provided so we made our own coupler center pin mount from solid .125" styrene using the prototype dimensions for positioning the center pin on the model. The bar is mounted perpendicular to the center of the model between the steps, as shown in Figure 3. The bar is drilled with a #55 drill and along with the brass beneath it and then tapped for 0-80 screw. An 0-80 washer is placed between the fashioned drawbar and the car body. I have affixed the bar stock with both screws and ACC and have had no problems with either method.

7. The amount of play that you want in the drawbar depends mainly on the type of track upon which you will be operating, but, the SCTC has found that the combination of #55 drill, 0-80 screw and 0-80 washer seems to provide sufficient play for uneven track.

8. When we started this article with the second step, you may have thought that to be a typographical error. It was not. The first step is to acquire these couplers in the United States. The Kato part number is 1-410-C3. It is normally only marketed with the Japanese prototype multiple unit cars. Efforts to try and get U.S. distributors to handle these couplers so far have not been successful. However, as of March 1998, Custom Traxx, P.O. Box 641175, West Los Angeles, CA 90064-1175 has obtained a limited supply at $5.00/pair. Refer to the KH coupler when ordering.

PROCEDURE FOR INSTALLING THE Kato "H-2" COUPLER - METHOD TWO

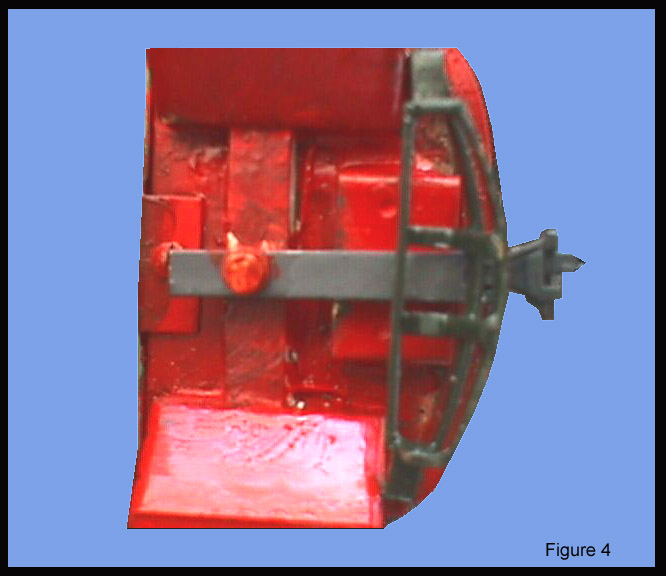

1. Again, the second step will be to remove the base of the coupler leaving only the shank. This is accomplished by cutting the coupler at the base of the triangular mounting hole area as shown in Figure 4 and then filing the shank down to the size that will slide snugly into a piece of K&S 3/32" square brass tubing (Walthers #370-0150).

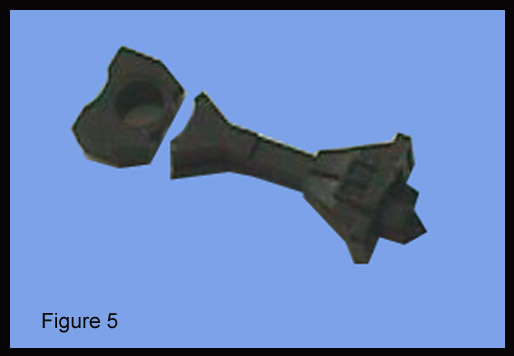

2. The next step is to prepare the drawbar to receive the coupler. To operate successfully, the coupler connector is mounted on a split shaft which allows sufficient freedom vertically for this coupler connector to operate. To maintain this freedom in the new drawbar, a small notch is filed into the base of the brass drawbar as shown in Figure 5 .

3. The coupler is then inserted in the prepared end of the tubing in a manner that the coupler connector shank fits just beneath the notched end. If inserted correctly, the coupler connector shank should have sufficient room for vertical movement to uncouple without breakage. Once the coupler fit is made and a snug fit of the entire coupler shank can be made inside the square tube of the drawbar, remove the coupler and place aside as we will be soldering to the drawbar and prefer not to melt the coupler during this step (The author has a melted coupler to prove it).<

4. In attaching to the car body, more than likely you will have a coupler mounting hole already provided. If you are fortunate to have a local source of prototype data or better yet, a nearby museum where prototype dimensions can be readily obtained, you may use such data as a source of information.

a. We located a prototype at the Orange Empire Railway Museum and found that the distance from the coupler face to the center pin on a Hollywood Car was 72"; the distance from the center pin to the radius mounting bar was 54" and the coupler face was 15 inches from the face of the anti-climber. Also it is important to know that for these cars the center of the coupler was only 18 inches from the top of the railhead, almost half the distance required for steam road AAR couplers. The Suydam models do not follow these dimensions in this area, as the mounting screw (center pin) is only about 48" from the face of the anti-climber.

5. As mentioned earlier in this article, the radius of the coupler swing was usually concentric with the radius of the anti-climber or buffer, especially on street cars and interurbans where city curves had to be traversed. The best operation is obtained when any radial coupler is mounted in that manner.<BR>

6. On most of the imported HO scale "Hollywood" cars there is provided a mounting screw through a "U" shaped fashioned plate which can be used to maintain the coupler level and prevent it from dragging onto the track. This is crucial to effective operation as there must be sufficient vertical movement to avoid derailments while the coupler is only a foot and a half from the top of the rail head or the blacktop.

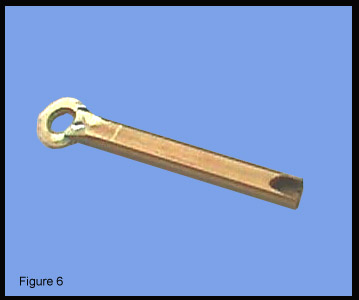

a. To mount the coupler to the body, we first decided the length of the drawbar. To ensure that the coupler clears the buffer throughout the entire radial swing, we discovered that the drawbar should be 36 scale inches long. You may make your own conclusions using the provided mount on other cars, or you can fashion your own mount using a 2-56 screw on the prototypical location. Using the stock brass bar, cut a horizontal notch 3/64" long in one end. This notch should be placed in the upper one-third of the brass tubing and should be angled slightly as shown in Figure 6.

b. Solder a brass 2-56 washer into the notch. The angled notch will enable the washer to maintain the coupler in a level state.

c. File the hole in the washer to clear the mounting screw provided. Do not overfile here. This is a careful file and fit maneuver until the mounting screw can pass through the modified 2-56 washer.

d. Attach the coupler into the opposite end of the drawbar with ACC. (We recommend CA4000 which is available from Dental Ventures of America, Corona, CA (909) 228-0606. They have what we feel is the best ACC applicator on the market.)

e. Mount the drawbar and ensure that the fit is correct.

7. The amount of play that you want in the drawbar depends mainly on the type of track upon which you will be operating, but, the SCTC has found that this method with slight adjustments of the U-shaped mounting plate provided on these cars worked for us.

8. Again, the first step is to acquire these couplers in the United States. However, as of March 1998, Custom Traxx, P.O. Box 641175, West Los Angeles, CA 90064-1175 has obtained a limited supply at $5.00/pair. Refer to the KH coupler when ordering.

ABOUT THE AUTHORS

The Southern California Traction Club (SCTC) was founded in October 1995 by six avid electric railway enthusiasts; George Huckaby, West Los Angeles, CA; Fred Burg, Downey, CA; Charles Hepperle, Torrance, CA; Bob Hill, Lakewood; CA; Fred Hutchins, Venice, CA; and Bill Kift, Long Beach,CA. At the time of the writing of this article, the club had added the following members; Byron Brainard, Laguna, CA; Mike DeGhetto, West Los Angeles, CA; Dave Garcia, Downey, CA; George Jones, Culver City, CA; Toshisuke Matsumoto, Tokyo, Japan; and Janik Podganski, Hawthorne, CA.

The club models electric railways in HO scale using both the modular approach and functional overhead wires. The cars actually receive their power from those overhead wires. All modules are based on the physical standards of the East Penn Traction Club while using a slightly modified electrical system. Although the majority of the cars operated are of Pacific Electric Railway prototype, vehicles of other operators, such as Los Angeles Railway (LARy), Los Angeles Transit Lines (LATL), Philadelphia Rapid Transit (PRT), Philadelphia Transportation Company (PTC) and Sacramento Northern Railway (SNRy) are often operated. Any HO scale electric railway vehicle that uses a trolley pole to collect current can be operated on the SCTC modules, subject to a few qualifications.

For more about the authors themselves, refer to the article on Pacific Electric paint schemes which is also in the Trolleyville Schoolhouse.

CONCLUSION

Any article placed on Trolleyville Schoolhouse is so placed to promote the model electric railway hobby and to aid those modelers who desire to model electric railways and can not seem to find the information or supplies that they need. These methods are not ultimate ends in themselves and some readers may find and already know simpler and even better ways to accomplish these tasks. All we ask that if you find an error in our presentation or know a better way, why not share it with us and the rest of the hobby. We choose not to respond to those who criticize and have no alternate workable suggestions.